Airplane Portholes: Triple Layers Revealed

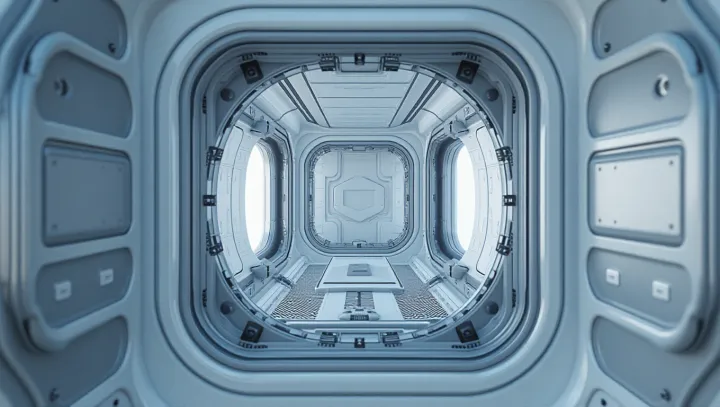

In a meticulous exploration of aircraft engineering, recent insights reveal that airplane portholes consist of a sophisticated tri-layer design. This structure is not merely aesthetic but quintessential for maintaining cabin pressure and ensuring passenger safety during flights. Each of these layers plays a critical role.

The outer layer functions as the primary barrier against external elements and is designed to endure extreme temperature and pressure differences. The middle layer often acts as a failsafe, reinforcing overall structure integrity. Finally, the inner layer provides an additional shield, offering passengers protection from the exterior environment and additional structural support.

Aviation expert Dr. Christopher Lawrence elaborates, 'The three-layer system is vital for mitigating the risk of depressurization and ensuring that the structural integrity of the window is uncompromised. This redundancy is essential for safety and security during high-altitude flights.' Given the airline industry's relentless commitment to safety, the complexity of these designs echoes broader trends toward upholding rigorous engineering standards.

Passengers flying globally benefit from this meticulous attention to detail, affording them peace of mind as they journey through varied climatic zones. This diligent engineering ensures that aviation remains one of the safest modes of transportation.